Coskata Inc., a developer of biofuels, today announced the successful start-up of its semi-commercial flex-ethanol plant in Madison, Pennsylvania.

The operation potentially represents a successful scale-up of company’s experimental technology. It could evolve into the world’s first commercially-viable ethanol process that would use bio-mass rather than foodstocks, such as corn, which are currently used for the mass production of ethanol.

U.S. energy policy, which grants ethanol a 52-cent per gallon taxpayer subsidy to politically connected farmers, is controversial since production of the fuel over its life cycle consumes as much or more energy as it produces. Furthermore, numerous studies have shown that if ethanol were to replace oil, people would starve from the resulting lack of grain in the world’s markets. U.S. tariff policy also effectively blocks the importation of sugar-cane-derived ethanol from Brazil, currently a much more efficient process.

It is thought that using biomass – inexpensive farm waste – could radically alter the economics of ethanol. For example, making ethanol from the cellulose of plants is less costly than using corn grain. Switch grass, a crop that grows readily in the U.S. east of the Rocky Mountains, and corn leaves and stalks or other crop wastes are cheap to acquire and potentially solve the starvation issue. The lower cost could also end the huge taxpayer subsidies, although the farm lobby holds powerful sway in the pay to play Washington scene.

“We are proud that we have successfully scaled our technology to this significant level,” said Bill Roe, president and CEO of Coskata.

“This facility is demonstrating that our efficient, affordable and flexible conversion technology is ready for commercialization. The next step is to build full-scale facilities and begin licensing our technology to project developers, project financiers and strategic partners,” he claimed.

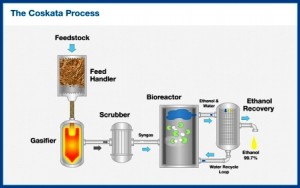

Unlike other technologies and facilities that may rely on one primary source of feedstock, Coskata’s flex ethanol facility will be producing ethanol from numerous feedstocks, including wood biomass, agricultural waste, sustainable energy crops, and construction waste.

Does it scale?

A large question remains about whether or not the facility can be enlarged to commercial levels of production and if investors will be forthcoming with what could be its $400 million cost, roughly six times the cost of conventional ethanol plants, which are currently losing money.

The facility is a demonstration of “minimum scale engineering,” which means it is the smallest size in theory that will still allow the company to scale directly to 50 million and 100 million gallon facilities.

Some of the ethanol that is being produced at the facility has been delivered to the General Motors Milford Proving Grounds for early testing, as well as to another “major strategic partner.”

“We invested in Coskata so that we could enable the rapid deployment of commercially viable and environmentally sustainable ethanol globally,” said Bob Babik, GM Vehicle Emissions Director. “We’re proud to say that we have already accepted some of Coskata’s ethanol at our Milford facility.”

Globally, General Motors has produced more than 5 million flex-fuel vehicles to date. In the U.S. alone, there are more than 3.5 million GM flex-fuel cars and trucks on the road. For the 2010 model year, there are 17 E85-capable flex-fuel models from the Chevrolet, Cadillac, Buick and GMC brands. GM is on track to make more than half of its vehicle production flex-fuel capable by 2012.

Coskata claims its technology, as demonstrated through Project Lighthouse, will be able to reduce greenhouse gasses by as much as 96% over conventional gasoline, while using less than half the water that it takes to get a gallon of gasoline. In addition, is says it can produce non grain-based ethanol that is as much as 7 times as energy positive as the fossil fuel used in the process.