The idea of an SMA heat engine has existed for decades, but the few devices built were too inefficient to make it worthwhile.

General Motors R&D received a $2.7 million federal award on Monday that will help build a prototype using Shape Memory Alloy, or SMA, that would generate electricity from the heat in automotive exhaust.

The grant from the Department of Energy’s Advanced Research Program Agency – Energy, or ARPA-E, was the onlyone to an automaker among $151 million in taxpayer funds distributed by the DOE.

The idea of an SMA heat engine has existed for decades, but the few devices built were too inefficient to make them worthwhile. Even now, GM admits the technology is in early stages and is “high risk.” During the next two years, GM and its partners will try to create a working prototype.

GM will collaborate with HRL Laboratories; Dynalloy, Inc., a manufacturer of shape memory alloys specially made to be used as actuators; and the Smart Materials Collaborative Research Lab at the University of Michigan.

The amount given to GM for SMA work is minuscule compared to the first three auto loans totaling $8 billion for developing advanced technology that were granted to the Ford Motor Company, Nissan Motors and Tesla Motors back in June by DOE as part of its Advanced Technology Vehicles Manufacturing program.

The loans, dubbed 136 for the section of the Energy Independence act that authorized it, have $25 billion in U.S. taxpayer funding.

Taxpayers fronting this money in the 136 program, which goes back to the Bush Administration, get stock warrants in return for the “loans.” Neither GM nor Chrysler qualified for the loans because of their financial status.

The $8 billion awarded here is for the development of advanced vehicle technologies, which include $5.9 billion for Ford Motor Company to “transform factories” across Illinois, Kentucky, Michigan, Missouri, and Ohio to produce 13 more fuel efficient models; $1.6 billion to Nissan North America, Inc. to retool its Smyrna, Tennessee factory to build advanced electric automobiles and to build an advanced battery manufacturing facility; and $465 million to Tesla Motors to manufacture electric drivetrains and electric vehicles in California.

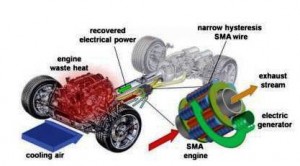

In the case of the DOE grant yesterday, GM says that heat from your car’s engine exhaust will be captured and converted to mechanical energy in amounts large enough to power a stereo, power seats and air conditioning.

“When you heat up a stretched SMA wire, it shrinks back to its pre-stretched length, and when it cools back down it becomes less stiff and can revert to the original shape,” said Jan Aase, director of GM’s Vehicle Development Research Laboratory. “A loop of this wire could be used to drive an electric generator to charge a battery.”

GM declined to name a vehicle where this technology could work, but either expensive hybrid or conventionally-powered vehicles are possible applications.

“No one else anywhere in the world is doing this work as far as we know,” Aase said. “In a hybrid system, the electrical energy could be used to charge the battery. In a conventional engine, this could perhaps even replace the alternator without any load on the engine.”

GM has an uneven record, at best, of converting the billions up billions it used to spend on advanced research into products that customers wanted to buy. If GM is going to survive, it needs to demonstrate that it can increase its market share and absolute sales with innovative products with features that are useful to customers.

“The days are gone when we would do this kind of groundbreaking work on our own. We need to continue to find ways to combine our deep technical knowledge with others who can help take our ideas from concept to commercialization,” said Alan Taub, GM vice president of global R&D.

“We’re taking advantage of a network of people that we’ve been working with for a number of years on shape memory alloys,” Aase said. “And we have some novel approaches to make this high-risk, high return project successful.”