Among other imperatives, like improving fuel economy, automakers are under pressure to develop products faster, and at lower cost. An engineering firm thinks it has found a new way to achieve those goals, and the Society of Automotive Engineers (SAE) and the Massachusetts Institute of Technology Enterprise Forum (MITEF) agree.

At a recent dinner meeting SAE and MITEF selected Troy, Michigan-based Engineering Technology Associates (ETA) as a winner in this year’s Innovation Accelerator Competition.

(Judges also awarded a prize to a Massachusetts start-up that is working to make batteries last longer. The winners gain consulting time with industry gurus who will help them bring their technology to market sooner than otherwise possible.)

Time-to-market is a critical metric for automakers mired in an ongoing sales slump made worse by the intense pressure to innovate in order to differentiate despite resource limitations. They cannot survive without sophisticated software tools – and combinations of tools – designed to save time, lower cost, and make it possible to try out many different concepts without having to actually build any of them.

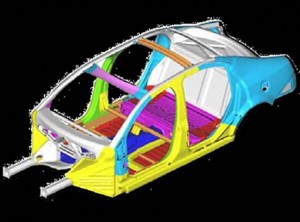

Innovation Accelerator winner ETA is thinking along those lines. It developed an Accelerated Concept to Product (ACP) process that, according to Akbar Farahani, the firm’s vice president of global engineering, uses multiple CAE (computer-aided engineering) software tools to generate an optimal design solution.

Farahani notes that the traditional design cycle consists of designing, analyzing and testing, redesigning, then testing and analyzing all over again. “Contrary to conventional methods, where just one or a few design concepts are evaluated, with the ACP process hundreds of design concepts are evaluated simultaneously,” he says. Concepts are eliminated if they fail to meet design, cost, timing, and manufacturing objectives.

The Auto/Steel Partnership used ETA’s new process in a Future Generation Passenger Compartment (FGPC) project and achieved a 30% reduction in mass for the new passenger compartment compared to the compartment in a baseline vehicle.

“In these trying economic times, it’s good to remind ourselves that this industry has a wealth of innovations in the pipeline,” says Dennis Nash, president of the MIT Enterprise Forum’s Great Lakes chapter.

“One of the greatest challenges faced by inventors is having their ideas introduced to, and evaluated by, automakers and Tier One suppliers. This competition addresses that need. Participants are given valuable feedback to improve their business case, focus on the required criteria and identify market conditions that impact adoption of their idea.”