Millions of car drivers suffer from injuries to their cervical spine caused by low-speed, rear-end collisions. It’s a global problem. Whiplash, or more properly “cervical spine syndrome,” is a painful, expensive outcome of fender benders. With the latest technology, whiplash is also largely preventable.

Much research and development work has been devoted to whiplash because of the billions of dollars spent on medical treatment each year, to say nothing of the legal costs from lawsuits, real or frivolous.

Independent studies show that head rest protection systems can reduce the risk of long-term damage caused by whiplash more than 50%, while the danger of injury to the cervical spine is lessened by about one-third.

One supplier, Johnson Controls, is currently the only one offering automakers both types of current production head restraint versions, either expensive proactive systems and less costly reactive ones. The company sells both types under the brand name “riACT.” (I apologize for the mangled “commercial” English.)

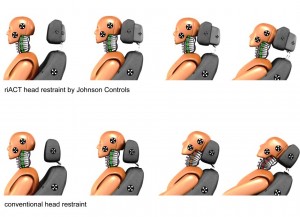

The design of riACT allows the head restraint to move close to the back of the head during a rear-end collision – regardless of the initial occupant selected position – so that the relative backward movement of the head and the subsequent whiplash are prevented or at least strongly reduced.

If a rear impact occurs, the most important design factor is to bring the head rest cushion close to the back of the head as quickly as possible, bracing the head and preventing its backward displacement – an occurrence which is potentially hazardous.

“The head restraint thus needs a signal in order to be released,” says Alexander Hasler, sales director foam at Johnson Controls Automotive Experience. “The difference between our reactive and proactive riACT systems is how this signal is provided.”

Reactive systems use body movement to signal a crash, making the occupant serve as a crash sensor. When the body is pressed into the lower section of the backrest during a rear collision, the resulting surface pressure triggers a mechanical actuator in the backrest, which then tightens a Bowden cable. This leads through the backrest into the head restraint and propels a telescoping mechanism that propels the head rest forward.

“About 50 milliseconds after the impact begins, or 25 milliseconds after actuation, the head restraint cushion reaches its final position – in either case, early enough to ensure that the system achieves its full effect,” says Hasler. He says this is based on results of internal tests, which are also confirmed by the Euro NCAP (European New Car Assessment Program) crash test data, where the system received the highest score ever recorded.

While the reactive system is actuated by the movement of an occupant’s body in the event of an impact, the proactive head restraint uses crash sensors to detect an accident. This information also controls the seat belt pretensioner and other restraint systems in the car. These sensors directly signal a small explosive device in the head restraint once a predefined acceleration value has been exceeded – instantly moving the head restraint into its protective position.

“By eliminating a range of mechanical components and providing faster information through the crash sensor, the proactive head restraint moves to its final position within about 25 milliseconds after the crash signal,” said Hasler.

This external activation has distinct advantages especially when the sitting position, weight or size of the person to be protected differs from an average assumed in the calibration of reactive systems.

Not surprisingly, this is a more expensive approach that vehicle makers are using on more expensive vehicles.