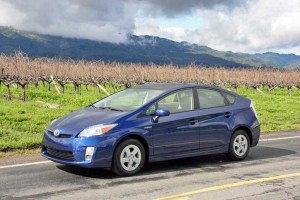

Storm clouds on the horizon? With a battery supplier down, could Toyota be facing a Prius shortage - and rising prices for buyers?

If you’ve got your eye on a new Japanese car, truck or crossover, you may need to stretch your budget a bit more than you anticipated. A number of online services that track automotive pricing report that Asian makers and their dealers are already beginning to curb incentives and even raise prices in the wake of the earthquake-fueled crisis that has all but shut down the Japanese auto industry.

While makers such as Toyota, Nissan and Honda say they have adequate supplies available for U.S. customers, the situation clearly depends on which product you’re looking for. With fuel prices at two-year highs, demand was already on the rise, prior to the quake, for hybrids and other high-mileage vehicles, such as the Toyota Prius and Honda Fit.

And with most of the automotive assembly plants in Japan still closed, vehicle shortages are mounting. Things are a bit better here, where only Subaru has halted operations at its Indiana-based “transplant” assembly line due to parts shortages. But analysts worry that more transplants could soon feel the impact.

And Japanese makers aren’t the only ones affected by the magnitude-9.0 earthquake, last Friday, and the subsequent tsunami. American automakers also rely on Japanese-made parts, notably including the electronic chips used for various engine controllers, safety system and infotainment devices – as well as batteries used in domestic hybrid models.

Citing unspecified parts shortages, General Motors has announced it will shut its Shreveport Assembly operation, in Louisiana, for all of next week. That facility produces the compact Chevrolet Colorado and GMC Canyon pickups.

The good news for GM is that it sources the lithium-ion batteries used in its new Chevy Volt plug-in hybrid from South Korea’s LG Chem. But other hybrids produced in North America could be running out of time. One of three Japanese plants producing the nickel-metal hydride batteries used in most conventional hybrids has been idled by the quake, leaving two others to pick up demand.

“We have yet to hear of any major damage to production (auto assembly) facilities” in Japan, notes a new report from Deutsche Bank. “The larger question is likely disruption to the supply chain.”

A sizable number of major auto parts manufacturers operated in the flat tidal plains in Northeast Japan, which was close to the devastating temblors epicenter. Toyota Boshoku, which supplies interior components to various Toyota assembly plants – including one in the devastated community of Miyagi – sustained significant damage. It’s unclear when the parts plant will resume operations or if Toyota can find alternative sources.

“It is still too early to estimate the impact to the supply chain or how long energy preservation measures (such as the rolling blackouts felt across much of Japan) could potentially limit production,” noted Deutsche Bank analyst Rod Lache.

But it appears that with only a few exceptions – including some Mitsubishi and Nissan assembly lines – vehicle production in Japan will remain down until at least sometime next week.

Major makers like Toyota, Nissan and Honda, now produce as much as two-thirds of the vehicles they sell in North America at U.S., Canadian and Mexican assembly plants. But those facilities are clearly vulnerable to parts shortages.

Meanwhile, some of the more popular Japanese-badged products still come from Japan, including Toyota’s Prius, the Honda Fit subcompact, Nissan’s big Infiniti QX56 SUV – and all of Toyota’s Lexus and Scion models.

Overall, Japanese-made vehicles account for about 12% of the products sold in the U.S., according to Deutsche Bank research.

And it appears that even while supplies are “adequate,” in Toyota’s words, consumers are already starting to pay more. Several services tracking Japanese car prices, such as CarWoo.com and TrueCar.com, are reporting that Japanese-badged vehicles are already seeing both direct price increases and a reduction in the incentives most makers were offering prior to last week’s disaster.

The situation comes at a bad time for American motorists, as it is just the start of the traditional spring buying season, the strongest selling period of the year. But even if Japanese automakers get back to business-as-usual in a relative hurry, TrueCar analyst Jesse Toprak warns that the price increases “will last weeks, if not months.”

Only strong competitive pressure from U.S., Korean and European makers would likely force a rollback. But then again, the entire industry could see an opportunity to boost prices, something that was difficult to do during the recession, when even the most lavish incentives failed to bring buyers back into the showrooms.