With Washington floating plans to raise federal fuel economy standards to as much as 56.2 mpg, many experts believe that hybrids could become the norm, rather than the exception, in the years ahead. But while today’s gas-electric technology may deliver a significant bump in mileage, it also results in a hefty cost penalty, on some models nudging up to $5,000 over a conventional powertrain.

A small British firm is developing what it claims to be a more cost-effective alternative – a totally mechanical system that eliminates the most costly and troublesome part of today’s hybrids, the battery. Already battle-tested during the grueling Le Mans endurance race, the so-called “flybrid” system could make its first appearance in automotive showrooms before the middle of the decade.

The technology is “smaller, lighter, more powerful and more efficient” than battery-based hybrids, claims Jon Hilton, Managing Partner of Flybrid Systems, which is based at the Silverstone race circuit in Northants, England.

But perhaps the biggest selling point is its price, somewhere between $1,800 and $2,000 a vehicle.

Like today’s gas-electric technology – such as the Hybrid Synergy Drive system used in the Toyota Prius – the flybrid is designed to recapture energy normally lost during braking or coasting. Current hybrids transform that energy into an electrical current that is stored in a battery pack. When the vehicle starts or needs an extra burst of power the energy is used to drive an electric motor connected to the vehicle’s driveline.

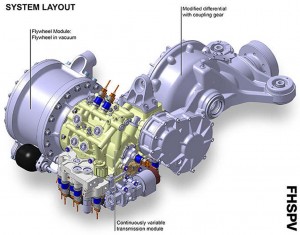

With the flybrid, energy is stored in kinetic form, spinning up a small plate, or flywheel. Linked to the driveline by a mechanical link, the flywheel transfers that energy back when it’s needed to help start or speed up the vehicle.

The flywheel actually isn’t all that new. The basic concept was developed in Neolithic times – in the form of the potter’s wheel. It became particularly useful in helping steady out the speed of the steam engines used to power the industrial revolution. You’ll find a flywheel on today’s automotive engines, as well.

But using a flywheel to store energy for use on demand is less common. Hilton notes there’s a tram in Birmingham that uses a flywheel to supplement its small gas engine. That system’s flywheel weighs more than 1,000 pounds and spins at a relatively slow speed of 60 revolutions per minute.

The Flybrid flywheel weighs barely 11 pounds, measures 8 inches in diameter – and spins at 60,000 RPMs. The outer edge of the flywheel is actually traveling at Mach 2, or twice the speed of sound.

The basic physics are surprisingly simple and translate into the fact that the faster you go, the more energy you can store kinetically. That means a prototype flybrid barely the size of the Manhattan phone book has been providing an additional 80 horsepower to a Jaguar XF the British company has been working with.

A larger, 38-pound flybrid system churned out a significant 135 hp almost instantaneously on an LMP1 race car entered into the recent 24 Hours of Le Mans by Hope Racing.

Theoretically, estimated Hilton, one of the developers of the technology, the flybrid could produce up to 200 hp, and would be suitable in applications ranging from minicars like the Nissan Versa or Ford Fiesta, all the way up to a medium-duty truck.

Flybrid Systems is currently working with nine different manufacturers, claimed Hilton, on a variety of passenger car and truck programs, including a manufacturer that sees a potential application on a 35,000-pound garbage truck.

The relatively modest price tag is one draw. Durability is another, as it’s still uncertain just how long the latest battery-based hybrids can operate without a motorist having to replace the battery pack.

Flybrid also notes that the compact size of its technology permits the system to be used in even the smallest vehicles without having to eat into passenger or cargo space – a definite problem with battery-based hybrids.

The Flybrid system does have its challenges. Linking a vehicle’s driveline with the flywheel system requires the use of an advanced transmission system, one that can reduce rotational speeds by a ratio of 700 to 1, a figure significantly more extreme than conventional automotive transmissions are required to deal with. There are several different options under development, notes Hilton, including one Flybrid designed on its own.

And flybrids aren’t an alternative for all hybrid applications. They tend to produce power in shorter bursts, so a maker that wanted to offer an extended-range, battery-only driving mode probably wouldn’t use the mechanical system.

The 4-year-old company is hoping that the flywheel-based system will soon be ready for prime time, and while Hilton won’t name names, he hints that production efforts are now underway. A major automaker, he reveals, will unveil a mechanically-based hybrid model using the Flybrid technology at September’s Frankfurt Motor Show.

The first vehicles produced “in the hundreds of thousands,” says Hilton, could be in showrooms before decades end.