Automakers are under pressure to sharply reduce the amount of fuel used by their cars, trucks and crossovers. But Ford Motor Co. is taking aim at the energy needed to build those vehicles.

The maker says it has already trimmed the energy requirements of its assembly lines by 20% since 2006 and wants to slash that by another 25% between now and 2016. Ford isn’t the only maker looking to trim energy use, however, and General Motors this week will begin drawing much of the energy for one of its larger plants from the sun.

“Sustainability has moved from the periphery to the center of our strategy for succeeding in the marketplace and helping to address global challenges,” said Robert Brown, Ford’s Vice President for Sustainability, Environment and Safety Engineering.

Producing an automobile is an energy-intensive process, according to the second-largest U.S. maker.

These days, the typical vehicle takes about 20 man-hours of labor as it moves down the line but in terms of power consumption it draws enough current to keep the lights on in a typical Midwest home for about five months – or about 2,778 kilowatt-hours.

That covers everything from the lighting and air conditioning of the plant, the moving assembly line and the robots that now handle the vast majority of body welding for the typical Ford product.

The good news is that’s down from about 6.3 months worth of energy just six years ago, according to the annual Ford Sustainability Report, equal to 3,576 kWh.

The maker’s CEO Alan Mulally and Chairman Bill Ford are both advocates of greening the auto industry. The latter, the great-grandson of Ford Motor Co. founder Henry Ford, pushed to have the redesigned Rouge Assembly Complex serve as an example of ways to make auto manufacturing more sustainable. Among other thing, the assembly plant’s huge roof is covered with a variety of plant life designed to absorb rain water that might otherwise overwhelm local sewers. And the living roof can reduce heating needs in the winter and cooling demands in the summer.

That translates into potentially significant economic savings, as well, — which is why Ford is just one of many manufacturers looking to slash energy consumption.

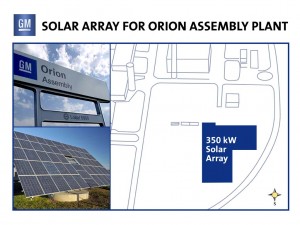

General Motors will today announced formal plants to add a large solar energy array at its Orion Assembly Plant. The array, developed in cooperation with local utility DTE Energy, is expected to generate as much as 350 kilowatts of electricity and reduce CO2 production by 261 metric tons.

The maker has been adding solar arrays at a number of plants – including the Detroit facility that produces the Chevrolet Volt plug-in hybrid.

“Last year, we committed to doubling our global solar output at our facilities from 30 megawatts to 60 by 2015,” said Mike Robinson, GM vice president, Sustainability and Global Regulatory Affairs. “We believe in harnessing energy from clean, renewable sources because there a solid business case to be made and it’s good for the environment. This array reinforces our progress.”

The Orion plant – which produces the small Chevrolet Sonic and Buick Verano models – already taps two nearby landfills for natural gas, something the maker says saves it about $1.1 million annually. Meanwhile, more efficient lighting has cut the plant’s energy bill by almost $600,000 a year.

Other makers that are sharply reducing energy consumption by turning to waste gas, solar energy and more efficient lights and equipment include Japan’s Toyota as well as Audi, which has set up solar arrays at a variety of its German factories.