It’s a milestone month for two of the largest Japanese automakers – or as they increasingly tend to bill themselves, two of the largest foreign-owned U.S. automakers.

Marking its 30th anniversary since rolling out the first American-made Accord, Honda says it will invest $200 million in its original Ohio assembly operations. Toyota, meanwhile, was a relative latecomer, launching U.S. production just 26 years ago, but that’s still given the Japanese giant enough time to reach 25 million vehicles assembled in the States.

“We continue to evolve as a company thanks to their commitment to build the best vehicles in the market,” said Steve St. Angelo, executive vice president of Toyota Motor Engineering & Manufacturing North America, Inc., toasting the workers at Toyota’s expanding production base here.

A 2013 Toyota Avalon rolls off the line in Georgetown, Kentucky, the 25 millionth Toyota built in North America.

The maker claims to have created 365,000 jobs in the U.S. alone, though only about 10% of that figure including employees of the maker itself. The vast majority are employed directly or indirectly by automotive suppliers and other vendors.

Meanwhile, Toyota says it has so far invested $24 billion in North American operations that include a score of assembly and parts plants, research centers that include an engineering complex in Michigan and a test track in Arizona, advanced design operations in California, sales headquarters in California and other facilities across the continent.

Ironically, Toyota was reluctant to come to the U.S. market, initially believing the hype that American workers couldn’t deliver the quality to match Japanese-made vehicles. It took a joint venture with General Motors – at an abandoned factory near San Francisco – to get Toyota to give it a try. It now operates the largest foreign-owned manufacturing network in the States.

And it’s likely to get bigger. In the wake of last year’s Japanese earthquake and tsunami – and the continued rise in the value of the yen – Toyota has been shifting more production out of the home islands. It is eventually expected to produce a version of the Prius in the U.S.

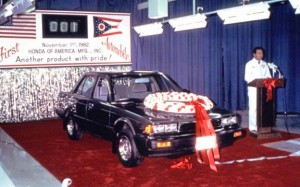

Honda was the first Japanese maker to open an American assembly plant. (Volkswagen beat it to the States but shut down its Westmoreland, Pennsylvania facility just as the Japanese were toying with U.S. manufacturing.) The first line produced motorcycles. Soon, a second operation in the farm town of Marysville, Ohio went into operation to produce the 1983 Honda Accord, the first rolling down the line on November 1, 1982.

(The first Accord is currently on display, curiously enough, at a recently updated automotive exhibit at the Dearborn, Michigan museum known as The Henry, for founder Henry Ford.

Like Toyota, expect to see significant expansion at Honda’s North American facilities in the coming years, and for largely the same reasons. The maker is currently planning to pump not only $200 million into Ohio – creating 200 jobs in the process – but will invest $1 billion to improve and expand the rest of its U.S. manufacturing system.

“For 30 years, Honda associates in our U.S. auto plants have challenged themselves and set high standards to create products that meet the needs of our customers here and in markets around the world,” said Tetsuo Iwamura, president and CEO of American Honda Motor Co., Inc., and chief operating officer of North American Regional Operations. “We continue to invest in our associates, helping to keep our operations in America on the leading edge of quality, efficiency and flexibility.”

The maker’s seven U.S. and Canadian assembly plants now have the capacity to produce 1.63 million vehicles annually and that will expand to 1.92 million with the addition of an eighth plant, in Mexico, in 2014. All told, Honda claims North American employment of 26,000.