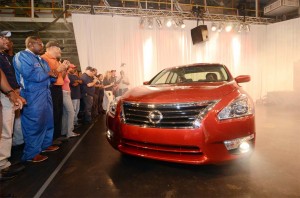

Nissan recently expanded capacity at its Canton, Miss. plant to handle the latest-generation Altima sedan.

With expanded operations in the U.S., and new plants in both Brazil and Mexico on tap, Nissan is projecting a big jump in production capacity in the Americas.

While the maker is targeting significant sales growth in North, South and Central America, increased exports are a major factor in the maker’s production push – which will see it boost capacity to more than 2 million in the Americas by the end of 2014, it says.

The second-largest Japanese automaker is in the midst of a $5 billion investment program that includes its two assembly plants in the U.S., as well as new operations in Latin America. In all, it expects this “response to strong growth opportunities” to generate, according to a corporate statement, “more than 10,000 jobs across the region, with much of that hiring complete or underway.”

Said Bill Kruger, senior vice president of purchasing and manufacturing for Nissan Americas, “While we quickly increase our capacity to satisfy local demand in the region, Nissan s U.S. plants have been charged to take a lead role in the production of some of our most important global models. As a result, more American-built Nissan vehicles will make their way to more global markets than ever before.”

A major part of the plan centers around a $2 billion manufacturing complex going into Aguascalientes, Mexico where Nissan is currently the industry sales leader. The facility will boast production capacity of 175,000 units annually of Nissan’s B- or small car platform.

(Nissan has big plans but can it achieve its goals? Click Here for TheDetroitBureau.com’s report.)

The Nissan complex may eventually serve as a manufacturing base for luxury products, as well, as Daimler AG is considering building its own plant on the sprawling campus. The German maker’s new compact luxury architecture will eventually serve as the platform for new Infiniti models as well as for such Mercedes-Benz lines as the A-Class and new CLA.

A new line of four-cylinder engines, meanwhile, will begin rolling out of an all-new plant in Decherd, Tennessee early next year. Run as part of the global Renault-Nissan Alliance, the plant will provide up to 250,000 engines annually for use in both in Infiniti products as well as Mercedes models set for production at the German maker’s own assembly plant in Alabama.

(Nissan concept set for Detroit will reveal maker’s “future design direction.” Click Here for a closer look.)

Along with the Mexican assembly operation, Nissan is meanwhile in the midst of setting up a new, $1.5 billion USD manufacturing center in Resende, Brazil. Set to begin operations during the first half of 2014, the factory will be able to produce up to 200,000 vehicles annually based on Nissan’s V platform.

Even with a weaker yen, Nissan has moved a significant amount of capacity out of its Japanese home market in recent years, much of it to the Americas. The Mexican operation has several key advantages in that it not only offers a low wage base but can also take advantage of the a wide range of free trade agreements that country has negotiated in recent years to boost exports.

But Nissan also plans to expand its export base from the States, projecting it will “nearly double the number of export markets…its U.S. plants…will be able to serve by 2015,” according to a statement.

With the recent shipment of U,S,-made Nissan Pathfinders to Australia and New Zealand, the maker currently counts 61 global export markets. It says that will jump to as many as 119 next year when the Canton, Mississippi plant becomes the global source for the Nissan Murano.

About 12% of Nissan’s U.S. capacity was earmarked for export in 2012. That is expected to approach 14% this year and continue to grow, the maker said.

(Infiniti lures away key exec from Porsche. Click Here to find out more.)