Hyundai has begun delivering the new 2015 Hyundai Sonata to dealers across America from its bustling assembly plant in Montgomery, Alabama, a factory stretched well beyond its rated capacity as the Korean carmaker struggles to keep up with consumer demand.

The Montgomery plant, which has 3,000 employees, now operates on three shifts five days per week and last year built a total of 398,000 vehicles – nearly 100,000 more than what it was built to handle when it opened a decade ago.

Dave Zuchowski, president and chief executive officer of Hyundai Motor America, noted the ability of the Montgomery plant to expand production beyond the rated capacity has been critical to Hyundai’s ability to meet customer demand in recent years.

Even then, Hyundai could use more capacity in the U.S., noted former Hyundai CEO John Krafcik, who left the company last December. But Hyundai has added employees to staff three shifts at the Montgomery plant to increase the utilization of the $1.7 billion assembly complex, which contains a highly automated stamping plant and an engine plant, as well as its assembly line.

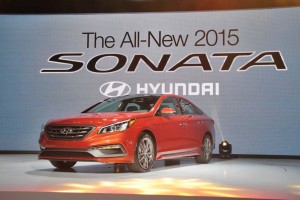

The 2015 Hyundai Sonata debuted in New York with a toned-down design compared to the prior generation.

“We’ve really pushed the plant hard,” Zuchowski told reporters during a tour of the complex marking the launch of the 2015 Sonata. “We’re having a hard time keeping up with demand and the ability of this plant to overproduce is critical.”

(Hyundai one of the brands likely to post strong sales for June. Click Herefor more.)

The launch of the Alabama assembly line marked a significant transition for Hyundai, and demonstrated that it could be competitive without having to rely on the cheaper wages of its plants back home. A full 50% of the vehicles Hyundai sells to its American customers now are built in the U.S., Zuchowski noted, either in Montgomery or at another plant in West Point, Georgia, which is operated by its partner Kia. That plant is 81 miles east of Montgomery.

Zuchowski said Hyundai sold more than 700,000 vehicles in 2013, and while it may not pick up market share, it expects to boost U.S. demand to a record 745,000 this year. The plant also has been critical in Hyundai’s efforts to establish a reputation for building quality vehicles, the CEO said.

“We have been building really good product for a very long time,” said Zuchowski, who pointed out that the company’s claims are now supported by a long string of third party endorsements – most recently in J.D. Powers’ closely watch Initial Quality Survey, where it was the highest-ranked mainstream brand.

(Click Herefor more on the 2014 J.D. Power IQS.)

“We ended up fourth behind Porsche, Jaguar and Lexus,” said Zuchowski, who noted the Hyundai brand’s growing reputation for quality is helping attract new customers and help it shift its image from that of an economy brand to one that emphasizes value.

“We know we are attracting completely different buyers than we did,” Zuchowski said, “and loyalty has helped accelerate our growth.”

Zuchowski said the sixth generation Sonata, which is now being replaced by the 2015 model, was a “breakthrough” vehicle for Hyundai. “For the first time ever we became relevant,” he boasted.

The average age of the typical Sonata buyer has dropped from 61 to 56 and the household income has increased from $77,000 t0 $81,000. In another sign of the Sonata’s appeal, buyers also become more diverse.

(Click Here for a review of the all-new, 2015 Hyundai Genesis Sedan.)

Ashley Frye, vice president of production, said the quality of the new Sonata has everything to do with the future brand image of Hyundai in North America.

“To continue this momentum, the 2015 Sonata sedan must be delivered to Hyundai dealers with zero issues from the assembly process,” Frye stressed. “Our Team Members have the control to stop a quality issue in its tracks, they have the responsibility to install a component the right way or reject a supplier part that does not meet our quality standards.”

Hyundai executives describe the highly automated plant as one of the most modern ever built. The plant’s integrated stamping operation is completely automated, as is the body shop, which includes 280 robots, which build and weld the underbody and front structure as well as the floor pan and roof. The plant’s paint shop is also highly automated.

The longer-term question is whether Hyundai will need to expand the Alabama operation – or add a new facility. The maker isn’t talking about its future plans, but it has made it clear that even by boosting the factory’s output it is struggling to meet U.S. demand. So, if it expects to match the pace of the overall U.S. automotive market’s growth, Hyundai may have to make some decisions in the very near future.

I test drove a 2015 Sonata and it is a substantial improvement over my 2011. A factory working over its design limits? I think I’ll keep my checkbook in my pocket for awhile and see how this turns out.

Randy, remember, that was straight-time capacity. A lot of plants go over design limits when times are good. The alternative is to build a new plant for the peak years and then close it, or operate at a big loss the rest of the time. And that usually would mean idling workers in the soft years.

Paul E.

I have to agree with the previous poster.

Also, for a few more dollars you can get a better car.

A few more dollars for a better car? Hyundai and Kia both are topping non-luxury quality surveys. The K900 from kia is tops in the Luxury quality list behind Porsche, Mercedes, Audi, and Jaguar. For a LOT more money maybe you can find your opinion of a better car, but Hyundai and Kia are producing a winng formula of quality, style, and performance.

I have a 2003 Kia Sorento (mid size SUV) with 200,000 miles on it. Would buy another one in a minute, regular wear a tear for a contractor this SUV has out performed many a domestic truck I’ve had in the past.

My 2012 Hyundai Equus skidded out of control on dry pavement with my grandchildren in the car. No one could explain why. They may have improved but need work on the suspension and braking systems. And my guess is that takes money which will narrow the price comparison between Hyundai and the luxury brands. JMHO

Hi, Mark,

We have long believed that the suspension and steering are the two weakest links in the Hyundai/Kia family. The good news is that company planners seem to agree and we’re beginning to see improvements. Why yours skidded like that is unclear and I’d be curious to have more details.

Paul A. Eisenstein

Publisher, TheDetroitBureau.com