Toyota will halt production at its Japanese auto assembly plants for a week due to a shortage of steel.

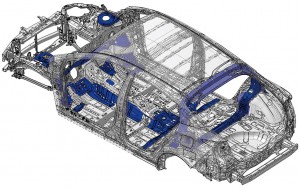

The week-long closure, which begins on February eighth, comes in the wake of an explosion at a steel plant operated by one of its key suppliers, Aichi Steel Corp. early last month. That has left Toyota struggling for the steel it needs for a variety of its operations, including powertrain and chassis components.

“Operations are scheduled to recommence on February 15,” Toyota said in a statement, “and vehicle production on lines outside Japan will not be suspended.”

(Toyota planning to buy out little Daihatsu. Click Here for the latest.)

The steel shortage is particularly problematic for Toyota because is more dependent on its home plants than any of the other major Japanese automakers. Of the 4.0 million vehicles those factories produced in 2015, Toyota exported 46%.

Like those competitors, as a whole, Toyota was walloped by the devastating earthquake and tsunami that struck Japan in 2009, but it took the industry giant even longer to get its production network back up to speed.

Complicating matters, Toyota is especially dependent upon a smooth and continuous flow of parts and raw material because of the just-in-time and just-in-sequence production system it helped pioneer. Its factories maintain only minimal levels of inventory – usually just hours’ worth of parts and components. So, shortages are felt quickly.

The tsunami – which also triggered a nationwide energy crunch as Japan shut down its nuclear plant network – was the most devastating disaster to disrupt Toyota’s system, but the maker also was forced to shut its operations in 1997 following a fire at a key supplier plant.

(Winter storm put freeze on January auto sales. Click Here for more.)

Toyota officials have been scrambling to find alternative sources to cover the supply of steel lost after the blast at Aichi. But it says it now can only maintain production through February 6th. The explosion hit a facility in Chita that produces specialty steel parts. The Aichi plant is expected to be back up and running by March.

It is unclear if the shutdown at Toyota’s plants might have to be extended. The maker earlier said that, “We will be monitoring our supply situation on a day-by-day basis and decide accordingly.”

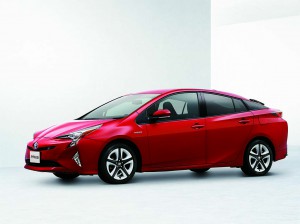

The situation comes at a particularly tough time for Toyota. The maker is just ramping up production of the fourth-generation Toyota Prius, the world’s best-selling hybrid, and routinely among the top sellers in Japan.

Production at Toyota’s Japanese plants rose 10%, to 13,600 vehicles a day, in December, as the new Prius started rolling down the line.

But Toyota volume actually dipped slightly for all of 2015, with global sales of just over 10.1 million. That was still enough to ensure it remained the industry leader for the sixth of the last seven years. Toyota has said it expects to see another modest dip in sales in 2016.

(Toyota retains global sales lead for 2015. For more, Click Here.)

The automaker hasn’t said how much production it will lose as a result of the steel shortage and shutdown – nor whether it expects to make up that lost volume later in the year.

This is rather interesting when China ships plenty of steel to the U.S.