BMW's Klaus Froehlich with the new i8 Roadster, Next Vision concept and i3s, which may all use solid state batteries in the future.

(Note: The name of Solid Power’s CEO has been corrected to Josh Buettner-Garrett.)

The race to develop next-generation batteries that could substantially increase range plus reduce costs – and dramatically improve the appeal of tomorrow’s electrified vehicles – is rapidly heating up.

Just days after BMW announced a new joint venture aimed at developing promising new solid state batteries, Japanese automakers Nissan and Honda have confirmed they are working on the technology, as well.

“Solid state technology is finally taking off,” Josh Buettner-Garrett, CEO of Colorado-based Solid Power, a start-up focusing on the new technology, told TheDetroitBureau.com. “What’s spurring all the recent activity has been (breakthroughs) that enable competition with lithium-ion for applications like automobiles.”

While a number of automakers have been sniffing around the research labs working on solid state technology, Toyota appeared to send off a signal flare when, earlier this year, it announced plans to partner with Mazda on the development of new electric vehicles to be built at a plant they’ll set up in the U.S. The maker strongly hinted it would opt for solid state, rather than lithium-ion batteries.

(BMW partnership aimed at developing next-gen EV batteries. Click Here for the story.)

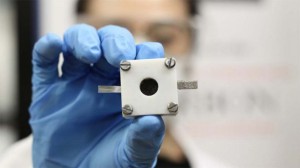

Solid state batteries face a few obstacles in their path to mass acceptance, including the fact they can only produced in low volume in a lab.

BMW earlier this month made it unambiguous, announcing its partnership with Solid Power, a spinoff of the University of Colorado Boulder. Volkswagen has also indicated it wants to switch from lithium to the new technology. And several other manufacturers have been dropping hints of their own.

A well-placed source from Nissan confirmed the automaker is looking at the technology, but is not seeking to partner with another manufacturer. Honda echoed that position to Reuters while confirming its own interest in the technology.

“The risk is that by not developing solid state batteries you won’t have access to the most advanced and least expensive technology when it becomes available,” said Stephanie Brinley, a senior analyst with IHS Automotive.

Solid state batteries are similar, in many ways, to lithium-ion technology, the key difference being that the flammable liquid electrolyte is replaced with a non-flammable, chemically doped ceramic material. The new technology has an energy density that should run double that of lithium cells when commercialized – though that could soon double again, according to some proponents. That means smaller, lighter batteries which would allow a carmaker to downsize a battery pack – or substantially increase range and performance.

Solid State batteries are also expected to be as much as 20% less expensive than lithium-ion, even as that older technology sees costs drop from around $200 a kilowatt-hour today to around $70 by 2023, according to the Boston Consulting Group.

A new solid state battery cell offers a wealth of advantages over the current lithium ion technology.

And while Solid Power’s Buettner-Garrett says it will take a while to achieve another target, he said, “The Holy Grail is to have … recharging your vehicle mirror the experience of refueling your gasoline vehicle.” In other words, just five to 10 minutes.

(Click Here for details about Toyota’s plans to use solid state batteries for its EVs.)

Solid State batteries have potential advantages for a variety of different applications, everything from smartphones to cordless appliances and tools.

That was why Dyson, the British appliance maker, indicated it was buying Sakti3, a University of Michigan spinoff, in 2015. In September of this year, Dyson announced it would use the batteries as it also launches its own line of electric vehicles, the company’s founder Sir James Dyson promising to invest 1 billion pounds, or $1.34 billion, to commercialize the technology.

There are a number of challenges still to be overcome:

- Solid state batteries are still not ready to operate in extremely low temperatures;

- They need to be proven to match or exceed the durability of lithium batteries in the harsh environment an automobile routinely faces; and

- They will need to be mass produced, not turned out in laboratory conditions in low volume.

But the growing consensus is that these targets are coming within reach. How soon is a matter of debate. Toyota’s team-up with Mazda, and a second joint venture with battery-maker Panasonic, could have it commercializing the first solid state batteries as early as 2021 or 2022.

“They’re at least five years off,” Henrik Fisker, the Danish designer who is trying to launch a new battery-car company, told TheDetroitBureau.com.

For his part, Buettner-Garrett wouldn’t discuss the plans his company has with BMW, but he said he would be surprised to see high-volume production before the middle of the coming decade.

(To see how mass EV charging could cause problems, Click Here.)

Even if it takes that long, the technology could take the industry significantly closer to the point where battery-car are appealing to consumers in their own right, without the need of government and manufacturer subsidies.

I wonder if solid state batteries can be made in the cylindrical (18650) shape. If not, Musk may have a retooling problem with his giga-factory.

Uncertain, but one goal for the solid state folks is using same or similar manufacturing tech so they don’t have to reinvent the wheel and can quickly bring down costs.

Paul E.