Battery-car pioneer Henrik Fisker has revealed a major change in the electric vehicle he plans to bring to market in 2019, dropping the cutting-edge graphene ultracapacitor technology originally in the works for the EMotion in favor of an advanced – but production-ready – version of familiar lithium-ion batteries.

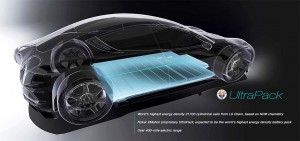

The Danish designer-cum-entrepreneur told TheDetroitBureau.com, in an exclusive Monday interview, that the Fisker EMotion will initially come to market with a 145 kilowatt-hour battery pack – about 45% larger than offered by Tesla – capable of delivering “well over” 400 miles per charge. The 800-volt system also will deliver significantly faster charges than current EVs, Fisker promised.

The move to a lithium-ion battery rather than a graphene system is a big shift from what Fisker had originally announced when the EMotion was revealed last year, but he explained that graphene “technology wasn’t ready for prime time, yet, and we didn’t want to miss our launch date.”

(Click Here for a review of the new Karma Revero.)

The former Aston Martin designer said Fisker Motors is still on target to get the EMotion in production by 2019, though several key obstacles have first to be cleared, including lining up an assembly plant.

Best known for the sleek and iconic Aston Martin DB9, Henrik Fisker has attempted to launch two car companies since striking out on his own a decade ago, including the ill-fated Fisker Automotive. That company brought out the Fisker Karma, a sexy plug-in hybrid sports car, but it collapsed in 2013, its assets sold to China’s Wanxiang Group – which recently reintroduced the four-seater as the Karma Revero.

Last year, Fisker announced he would try it again, this time focusing on pure battery-electric vehicles, or BEVs, starting with the EMotion. Beyond a sleek design to rival the older Karma, the real breakthrough appeared to be an alternative to the lithium-ion batteries used in most of today’s battery-based vehicles. Instead, the EMotion was to be powered by an ultracapacitor, the start-up claimed, that could yield a “theoretical” 400 miles per charge.

The source of a Nobel Prize in chemistry, graphene is a material finding widespread use in a number of different fields, but an automotive power source could have proven a major breakthrough in its own right. Fisker claims his company will continue to work with researchers from UCLA who were developing the new technology, but it is unclear when it will be “production-ready.”

Instead, Fisker Motors has turned to LG Chem, one of the leaders in automotive battery technology – among others, it provides the lithium-ion technology for both the Chevrolet Volt plug-in hybrid and Chevy Bolt EV.

(Click Here for more on the Fisker EMotion.)

There are actually more than a dozen different “families” of lithium-ion chemistries using a variety of different formulations to store energy. Each provides a different balance in terms of energy and power density – how much power they can store and how quickly it can be accessed – as well as charging times and reliability. Some formulations can store tremendous amounts of power but can’t survive in the harsh automotive environment.

Fisker explained that his new company will now turn to a lithium-ion formulation called NCM, short for the key chemicals of Nickel, Cobalt and Manganese. He told TheDetroitBureau.com that this chemistry is both highly energy dense and durable. To further enhance both energy density and battery durability, Fisker claims to have come up with a new battery “module” and a new cooling system.

The goal is to top 400 miles range, or about a third more than the longest-range Tesla vehicle currently on the market, the Model S P100d.

And because Fisker Motors will push the electrical system on the EMotion to 800 volts – double what most makers are using – it should significantly reduce charging times. Fisker said his company is working with Europe’s ABB to develop a charger that will be faster than current Level 3 systems. This could yield an additional 200-300 miles of range in well under a half-hour, an expert in battery technology told TheDetroitBureau.com.

According to Fisker, the company has set up its own, internal battery research team which is preparing to file for a number of new patents. That includes an even more advanced solid state battery that could substantially reduce the size and weight of a BEV’s power source while further boosting range and cutting charging times to “one or two minutes.”

A Fisker Emotion was spotted at Apple HQ in Silicon Valley. Could the tech firm be interested in using the EV as a platform for its autonomous system?

But he quickly added that “it’s not ready for manufacturing yet. It’s at least five years out.”

In the wake of the spectacular burnout of Fisker Automotive – and the struggles faced by a variety of newer battery-car makers, such as Faraday Future and LeEco – there are plenty of skeptics when it comes to Fisker’s latest venture. But he remains confident the project will move ahead.

And he is clearly generating some interest. The new company recently brought its EMotion up to Silicon Valley, where Fisker executives met with counterparts from Apple, Inc. The high-tech giant has begun to reveal hints about its own, long-rumored automotive venture, which appears to be focusing on autonomous driving technology. Exactly what the two companies discussed has not been revealed.

(For more on the Fisker-Apple meeting, Click Here.)

For his part, Henrik Fisker is nothing, if not bullish, and that applies, in particular, to his aggressive goal of getting EMotion into production by 2019. Unlike several other start-ups, however, Fisker Motors has no plans to erect its own assembly plant. Instead, the entrepreneur told TheDetroitBureau.com, he is looking at two existing facilities that could handle the EMotion.

“We are not high volume, so it doesn’t make sense for us to build a factory,” he explained, adding, “We are looking at two existing manufacturing facilities and we’ll make a decision by the end of the year.”