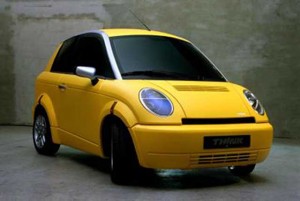

Despite a variety of financial setbacks, the Norwegian EV maker, Think, is gearing up to open a U.S. assembly plant for its plastic-bodied battery car, the Th!nk City.

By now, most folks might have bet that the long-struggling electric vehicle manufacturer, Think, would have come unplugged.

Yet despite the fact that the Norwegian company is in the Scandinavian equivalent of Chapter 11 bankruptcy, Think is getting ready to set up a U.S. manufacturing facility in one of eight states now under study.

The maker is looking to start marketing to U.S. fleet customers, in 2010, and open up a retail distribution chain a year later, according to CEO Richard Canny.

If some observers remain skeptical, there’s good reason. In the 17 years Think – or Th!nk, as the company prefers – has been operating in the U.S. market, it has sold a grand total of 2000 electric vehicles. It’s future seemed bright, a decade ago, when it was acquired by Ford Motor Co.’s hard-charging former chief executive, Jacques Nasser. But in 2003, following his ouster, Think was sold off as part of Ford’s “back to basics” strategy.

Since then, Think has been struggling to put together a viable business plan. The global downturn in auto sales, combined with the slide in fuel prices – which has slashed demand for high-mileage and alternative-power vehicles – led to the halt of production, in December, and the bankruptcy filing.

But Norwegian production could resume as early as may on the Th!nk City, a two-seat EV that can also be ordered with an optional rear seat. In European trim, it can reach a top speed of 62 mph (100 kmh) and achieve a range of 112 miles. For the U.S. market, Think would try to push he top speed closer to 75 miles, permitting safe freeway driving. It also hopes to improve range. The plastic-bodied coupe is just a bit larger than the Smart fortwo – for which a battery version also is being developed.

Borrowing on a strategy espoused by others entering the nascent EV market, Think is thinking about a combination lease/purchase strategy. Customers would buy the vehicle itself, for as little as $20,000. But the battery would be leased separately, for an estimated $90. That approach would minimize up-front costs, first of all, but also give consumers a sense of peace of mind, as they wouldn’t have to anticipate the costly replacement of a battery later on. Conceivably, Think could also offer an upgrade to a longer-range battery as technology improves, as anticipated, in the coming years.

Canny won’t go into detail about the U.S. plant site search, though Michigan and California are on the company’s short list. The proposed 60,000 square-foot factory would initially produce 16,000 City cars annually – about triple the estimated breakeven of 5,000 vehicles — and employ 300. But once retail marketing begins, Think hopes to boost production to 60,000 a year, and bring employment to 700 – including 150 at a new technical center.