More than a month after Japan was wracked by a series of natural disasters – and the subsequent crisis at a nuclear plant – Toyota Motor Co. is preparing to reopen its home market plants.

The maker revealed today it will resume operations on April 18th through at least the 27th, but at only half the normal capacity of that expansive production network. The 18 factories will then shut down again from April 28 through May 9, a traditionally holiday period in Japan.

The industry giant reports it has lost about 260,000 units of production since its factories were shut down by the 9.0-magnitude quake and tsunami that struck northeast Japan. It is unclear how many additional units Toyota will lose due to maintaining a reduced production schedule.

And it remains unclear what the maker’s plans will be following the Golden Week holiday. Toyota officials say they are slowly resolving problems related to parts shortages caused by the March 11 disaster. But they still are facing problems with at least 150 parts and components.

“There are problems with parts supply. But each day, we are doing our utmost to improve the conditions so that we can deliver cars to many customers,” said Toyota President Akio Toyoda.

The Japanese automotive crisis has been felt by all of the nation’s manufacturers, though a number of other makers have already begun ramping production back up. Toyota was especially hard hit, however, because it continues to produce a larger share of its vehicles at home when compared to major competitors like Nissan and Honda.

The shortages have impacted industry operations worldwide, and not just those of Japanese makers. Honda’s top American executive, John Mendel, told TheDetroitBureau.com that some of its North American “transplant” assembly lines are currently operating on half-time schedules – which could cause problems for the upcoming launch of the new 2012 Honda Civic. (For more, Click Here.)

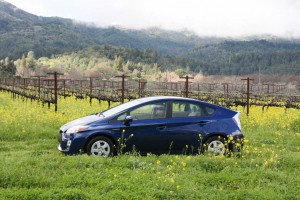

Toyota says it is all but inevitable it will have to idle its North American plants at some point. The maker is currently trying to steer parts, where possible, for use in its most important products, notably including the hot-selling Toyota Prius hybrid. But with sales slipping, U.S. dealers are now tacking on hefty premiums, as much as $3,000 for the Prius.

But General Motors has had to close plants in both the U.S. and Europe due to parts shortages. Ford and Chrysler have had to restrict orders of some models due to a shortage of certain paints using pigments only produced in Japan. Shutdowns have been reported at plants from Indonesia to Germany.

And “the situation is fluid,” warned Honda’s Mendel, who warned that his company still does not have a clear picture of what parts will be available – and thus whether it will be forced to trim or stop production at some plants over the next several months.

Nissan officials are issuing a similar warning.

Investors have been dumping shares of Japanese automakers, and some analysts say the crisis could be a boon for Detroit and European manufacturers who stand to gain sales if products like the popular Toyota Prius or Honda Civic fall into short supply.

But since most makers, wherever they are based, depend on at least some Japanese parts, “Everyone will be impacted,” warned Mendel, which could limit any shift in sales and market share.